Species Characteristic Matrix link is intended to provide a summary of the collective experience of Booth Veneers personnel relative to working with a wide variety of veneer species, and to provide a reference document that can be used to quickly understand and evaluate the risks and opportunities that specific veneers present. It is important to note that this summary is based upon generalities and the experience of those that provided input; exceptions to any description or characterization found in this documentation can and will be found.

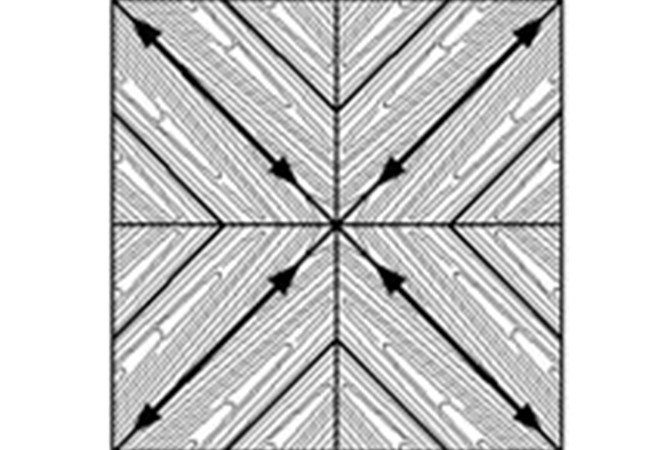

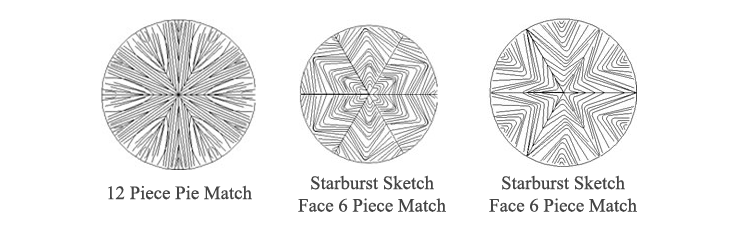

Pie match sketch faces can produce a myriad of patterns depending on the cut of veneer and the orientation of each veneer leaf in the pattern.

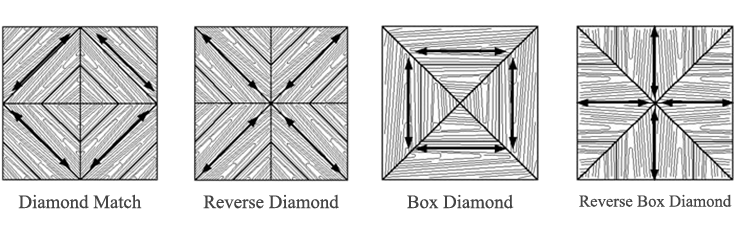

Grain direction shown with the arrows.

Sketch face patterns in Quartered Ebony

Lumber that matches perfectly to a specific veneer will never exist. However, Collins Aerospace- Booth Veneers is offering certain lumber species in 4/4, 6/4, and 8/4 stock that could be appropriate for many projects. Lumber from single logs are called boules and cannot be separated. Often, smaller quantities of some species can be offered.

Composite veneer is a man-made product using real wood, formaldehyde glues, and dyes. These offerings are fairly consistent and often simulate expensive, natural veneers. Proper cautions should be considered before using this product.

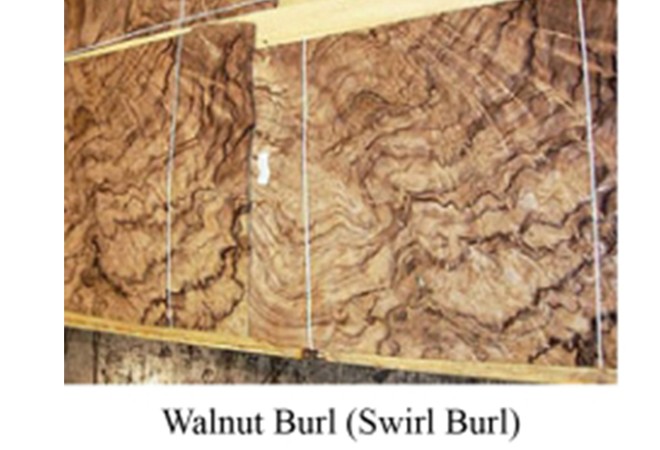

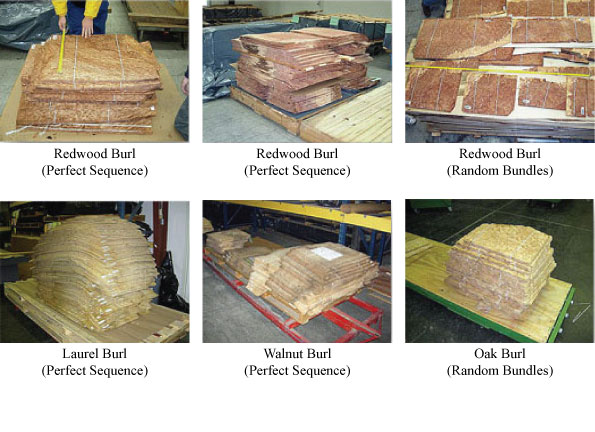

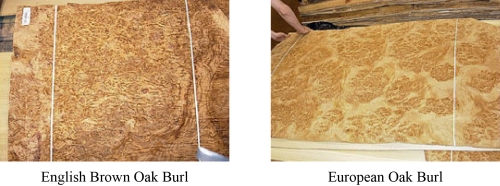

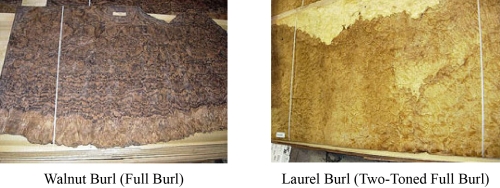

Many burls on the market today are random bundles of burl from the same log. Bundles clipped in sequence can produce burl panels that naturally evolve through an interior design.

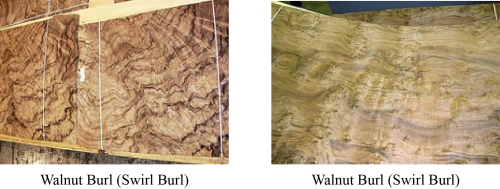

Burls are usually described as full burl, cluster burl or swirl burl. Many logs commonly display more than one pattern through each sequence. Many burls have two tone charter in some bundles.

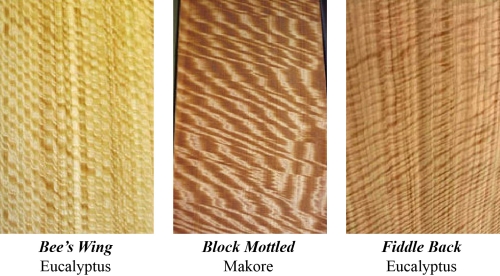

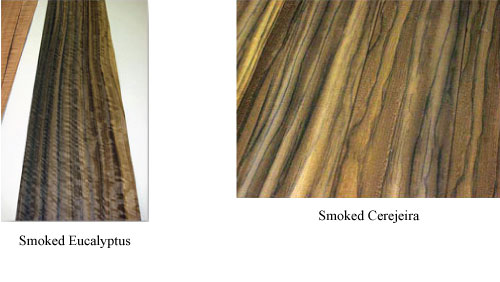

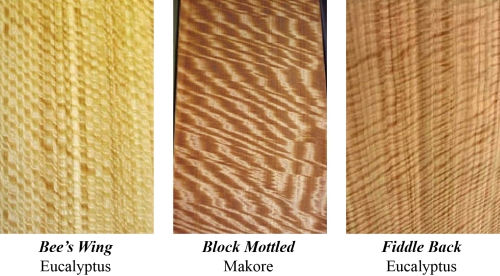

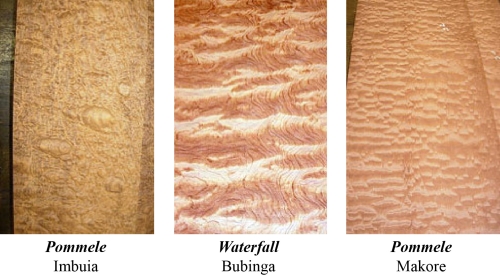

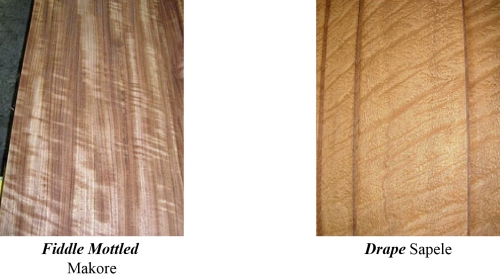

Figure is patterns on the veneer surface that usually run across the grain. Many figures have been described. A few of the more common forms are shown here.

Veneer sliced parallel to a radius is called quarter cut. Grain pattern will usually be fairly straight or have slight curves. Figure can be strong in quartered veneer.